|

About the Author: Fred Keislair is a member of the Zoetermeer Fire Department is a paid and volunteer department. He works in the Bureau of Training and also act as a lieutenant with engine co. 841 of Oosterheem Fire Station. We also cross staff the County Hazmat Unit and Water Rescue RIV. Part 1 | Part 2 | Part 3 | Part 4 | Part 5 This article is about my next

radio-controlled model. I recently finished (although I now know

that a working radio-controlled model is never really finished,

there is always something to improve or maintenance to do) and have

started on my next new model. Maybe it is hard for you to believe,

but the Sweet Lake City Fire-Rescue apparatus was a test model, to

learn how to make a radio-controlled model.

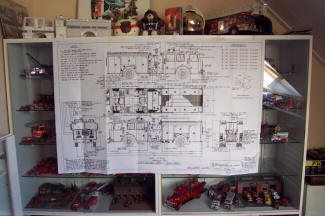

For those of you who couldnít recognize the company patch, I will give the answer. The model I will be making is the Seagrave Rescue pumper with the new Commander II cab, the apparatus of FDNY Squad company 61 with the ď9/11 never forgetĒ mural on it.

I was a FDNY buff long before

the attack on the WTC on 9/11 and had already made several FDNY

models, but in a smaller scale. As mentioned before, the SLFD rescue

pumper was only a test, and if you have read the feature about that

model you know that I had started way back with building a Mack CF

Aerialscope. So why did I decide to make that Squad unit, and

not another FDNY pumper. Well it was hard to get the drawings of

that model, and my first investment was buying the Code 3 diamond

plate model in 1:32, because then I would have a terrific model to

duplicate and I would simply have to double all the measurements to

get it in approx. 1:16 scale. The 9/11 mural and all the graphics

would make it stand out at any exhibition and last but not least, 61

is a special number for me, since Iím born in 1961. Does one need

more reasons to make this squad unit.

Making the monitor completely

remote controlled will be a challenge, but I will get it done.

A first test showed that the pump at full speed would empty the

water tank (cap. 0.7 liter) within 1.5 min, with a nice solid water

stream and a good reach of the water jet, which should knock down

any ďmodel houseĒ fire within seconds !!

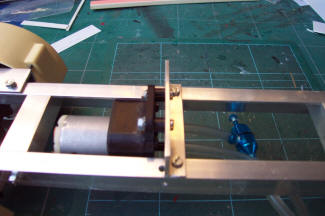

Picture 1: Close-up of the pump and hose

connections from the bottom of the tank. Since the tank is placed

over the chassis I had the make two connections to the bottom of the

tank to draft the water out.

Part 3

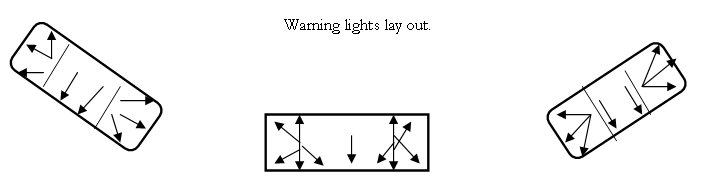

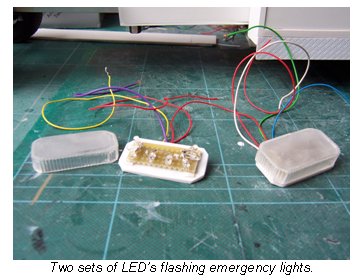

Since the last episode the building

of the body has come to a stop. But work has proceeded on the

warning lights. The original Squad 61 was delivered with the FDNY

style red and clear warning lights with rotators. But this was later

changed to the new LED warning lights. I choose to make this

version, the LED lights on the corners, and a red/white rotator in

the middle. But I wasnít sure what the color of the lights were, so

I got help from Ken, who sent me a picture with similar warning

lights on an other FDNY rig.

|

|

|

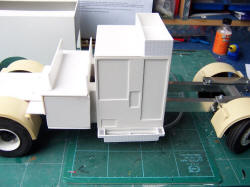

As you can see the plate has pins just like a

model kit. The ďLĒ means that I know that it is the Left side plate,

and on the second picture you can see that it fits perfectly to the

body. The body all ready has the outlines for the doors. But since I

have to find away to make the door handles, or slam locks, I havenít

made them yet. But you can imagine that it is real easy to make a

nice clean door, since I just have to measure the doors, cut them

out of a 1 mm. plate, and I have good sharp lines and door openings.

I have made one mistake on the left side, as I found out later.

Underneath the first left side compartment is the Airbag Storage,

and that means that the door isnít the same as the right side. There

is an extra tread plate covered storage compartment. This problem

can be changed easily, so that will be solved one of these days.

The rear of the hose bed has been worked on also. At his picture you can see that I made the hose bed.

In stead making it a straight flat hose bed, I

altered it a bit. The hoses on the model are going to be just one or

two layers, not a complete hose load and I need the storage space

underneath to house the batteries, and electronics. So that is why I

changed it. The rear step and the roll-up and compartment door above

it are also made using the take-apart-principle. It can be taken off

for painting and will be fixed after the whole body is spray

painted.

On top of the body one of the roof compartments is visible. I have

finished only one, since I ran almost out of Plastruc Diamond tread

plate. My local hobby shop has them on order for me, so I made other

parts that didnít need big pieces of this material like the front

bumper.

Also visible is the tread plate to the side of the body. I noticed

that on a picture I received of the real rig. I think that is one of

the many changes that are made to a fire engine that is frequently

used and are caused by adjustments requested by the crew who work

every day with the apparatus.

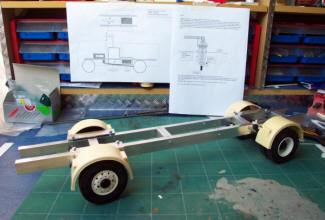

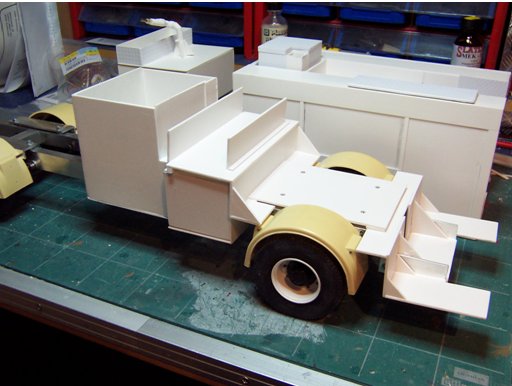

Underneath the body is the water tank and the storage room for the batteries and electronics. This picture shows you that I made a base plate over the chassis to house all the electronics. It is also used to get the body into place and to make the whole unit a solid truck. Since it will be Radio Controlled and it will drive around exhibitions a lot you donít want your model to fall apart after every run. So al the modules have to be secured by screws, or even Lego blocks to be kept in place (that is a trick a learned from a German friend who also has beautiful RC fire trucks).

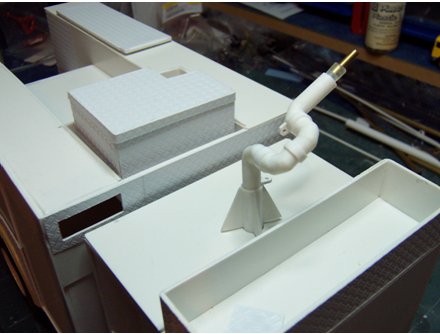

The next picture shows the Akron monitor, that will become fully functional. The nozzle tip isnít ready yet, that has to be made and for now I just put a small cupper tube in the hose. Inside the curved plastic tube is a flexible hose that allows the monitor to move vertically and by this I donít have to worry about leaking water (Keep It Simple SÖ. principle) If I donít succeed in making it move up and down while rotating the monitor will be fixed in a raised position and will only rotate approx. 270į. This option will eliminate a lot of the fun knocking down a model house fire, but if my solution that I figured out isnít 100% failure proof I will have to choose for this option. Nothing is so annoying as something that wonít work when you are presenting your model to the audience.

A parting shot, as they like to say in FAJ, the Code 3 Diamond Plate 1:32 scale model in front of my Platinum Plate Model to beÖ in scale 1: 14,5

Just to show you how the dimensions of this model are going to be.

Since the front bumper has been made after I

took these pictures, the next step will be making the cab. That will

be a turning point because then the model will start to look like

the real rig.

The making of : Squad 61Ē Part 5

After a long period of radio silence is here is a new episode of the

making of Squad 61. As you all may have noticed I have been

extremely occupied by making a Fire House to show at scale model

truck exhibitions. This station is now ready to use, although I

still want the doors to be motorized so I can open and close them.

An other project that I have finished is a FDNY battalion Chief

Buggy. This is a 1:16 scale Hummer, and I know that the FDNY doesnít

use those vehicles, but it was the closest I could get to look like

a Ford Explorer or Chevrolet Suburban. This model is fully Radio

Controlled, with a master switch for the receiver that also

activates the head and tail lights. The light bar is a Fredís custom

model, with two revolving lights. This time I left the lower part of

the clear cover unpainted so the white LEDís give a red and white

light. The siren is a 20 sec. electronic recording print with 16

secís of Wail and 4 sec of Yelp and then startís all over again.

At the rear two additional yellow flashers were installed on the

roof and in the front two red flashers between the head lights. When

parts of the Squad 61 model will be chromed the Bullbar and side

steps of this model will also be chromed.

Battalion 20 Chiefís Hummer, a rehab job on a toy model in 1:16

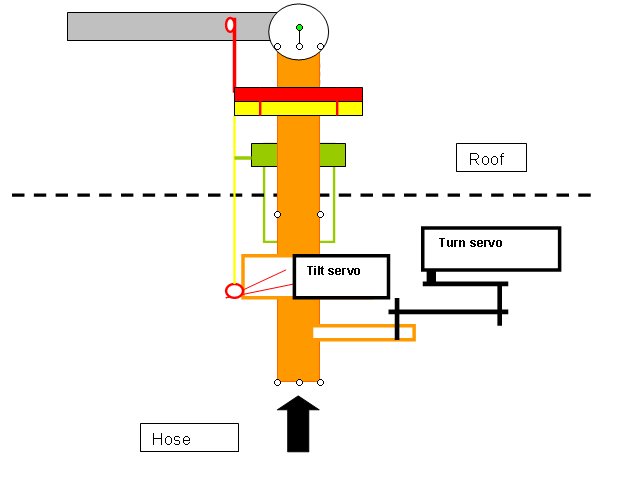

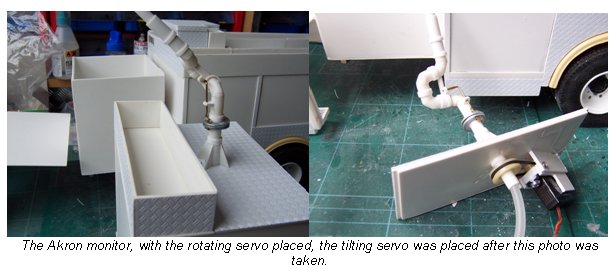

Work on the Squad had come to a stop due to problems making the Akron Monitor functional. I wanted the monitor to move horizontal and vertical in every position and that caused some problems. It is easy to lift the nozzle up using a servo, and its is easy to rotate the nozzle, but making these two functions work at the same time is something different. And to add another challenge to it I wanted the monitor to look like the original as much as possible.

The Akron monitor, with the rotating servo placed, the tilting servo

was placed after this photo was taken.

In these pictures you can see how I have solved this problem. The

first servo is to rotate the monitor using a rubber band and some

cassette deck wheels. The advantage of the rubber band is that if

the monitor is blocked it wonít cause any damage to the servomotor.

The tilting of the monitor is done by a small servo that moves a

metal ring up and down along the vertical shaft, and above that ring

is a second ring that is attached to the movable section of the

monitor. Inside the monitor is a flexible hose towards the end of

the nozzle, making it water tight.

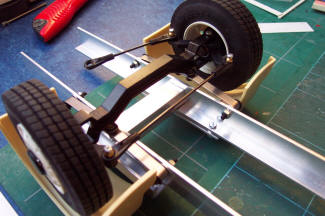

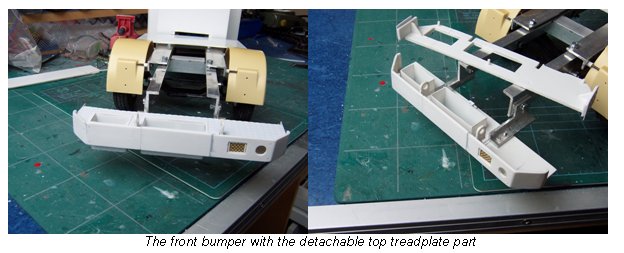

An other job that was done was the front bumper. This was a short

job for a weekend, and when I had it finished, using the original

drawings for measurements I discovered that it was 5 mm to wide

compared to the front wheel fenders. That would look really weird,

so I cut it into two, took out the 5mm and glued it back together.

The bolts on the front bumper are metal pins that you can find in

the collar of a new shirt when you open up the package.

The tread plate is not fixed, since I will have to install the side

mounted warning lights and paint the bumper and tread plate in

different colours.

During the Intermodellbau Exhibition in

Germany, (when you can drive two and a half hours to visit an

exhibition and stay in the USA, when I drive that distance Iím in an

other country !) I found what I had searched for. Bolts for the

front and rear wheels. These tiny bolts are chromed and make the

wheels look more like the original ones.

I also invested money in a master electronic circuit, so I can

connect all lights in the front and in the rear to two small prints

that are connected to the master print by small flat-cables. This

will make the electronics more fail safe and will look more

professional. This master print also has breaking lights function,

with an automatic switch off after 6 secís, and a directional lights

function that will also switch off automatically after a few seconds

after you have made the turn.

Next on the program is finishing all the big work on the compartment

body, closing the water tank, and installing the electric motor on

the chassis with drive shaft. When that is in place I can start on

the inside of the crew cab and the cabin itself.

Bad news it that I wanted to have the model finished around

September this year. But I have to be realistic, that is impossible,

but I hope to have to crew cabin and compartment ready by that time,

so it will starts looking like the real one.

I also spend time on making the lightbars. The LED bars on the outer

corners are ready, and tested, the center one with the three

rotators is still a challenge, allthough I have figured out a way to

get it done.

More bad news came after an other Exhibition.

There I found out while talking to a fellow scale modelbuilder that

I had mounted the rear wheels the wrong way. Adjusting this would

make the wheels stand wider apart, making it necessary to take of

the rear fenders and making them wider, and the front fenders, and

Ö.. take apart the rear body. This also implied that the front

bumper, that was to wide at first and that I had narrowed, was right

from the beginning! So I had to make a new front bumper also. The

good news is that now the measurements of the model are almost

exactly in scale, so that I donít have to adjust the width of the

model any longer but I can use the measures on the drawing.

Other good news is that while I had the rear body in pieces I made

some adjustments how to fix the body to the chassis. So it all turn

out good.

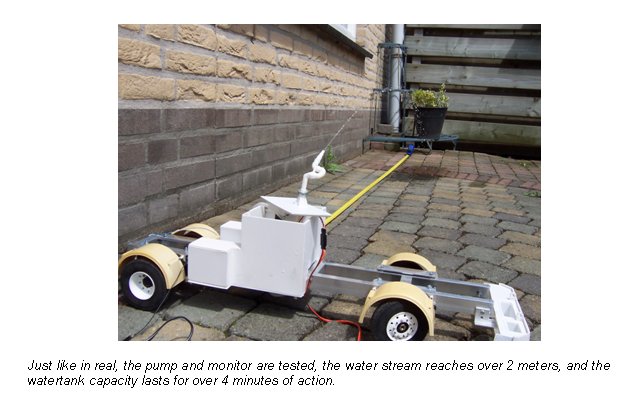

Just like in real, the pump and monitor are tested, the water stream

reaches over 2 meters, and the watertank capacity lasts for over 4

minutes of action.

Hope that you enjoy the photoís and since work

on the model shifted in to a higher gear a new up-date will follow

soon.

Fred